The Benefits of Lithium Batteries for Forklift Dealers

A wide range of repercussions are occurring across different sectors of the economy as the world recovers from the turbulent years of 2020 and 2021. As the Vaccines acceptance became more widespread and COVID deaths began to decrease around the world, the world woke up and demand started to skyrocket. The Lift Truck Industry started stronger than anyone expected in 2021. Some thought it was a catch up Blip – orders simply making up for the drop a year earlier – but now we have more than eclipsed that drop. It was impossible for some parts manufacturers to meet the growing demand due to all-time record order intake during the first and second quarters of the year.

In the MHI, inventory levels are low and lead times are long

Pricing started to rise after lead times moved out even more in the 3rd quarter. Due to low production in factories, shortages of inventory, and increased freight and part costs, nearly all fork lift manufacturers announced price increases. To help cover the rising global supply chain costs, logistic and freight surcharges were introduced for the first time in over a decade. Container pricing tripled or quadrupled.

According to the Industrial Truck Association’s data, the MHE order backlog in 2022 is bigger than ever. The lead time for Toyota, Crown, Raymond, and HYG has increased from the normal 20–30 weeks (pre-pandemic) to 20–30 months and, in some cases, up to 30 months. Toyota and Crown customers have reported long waiting lists. Some OEM dealers stopped taking orders in early 2021!

New Lift truck lead times before the pandemic averaged 10-16 weeks – today, those same trucks take 32-45 weeks to deliver, and some are more than a year away. The lead times for virtually ALL lift truck manufacturers are the same – no one appears to have been spared. A broken supply chain is not just affecting lift truck manufacturers – aerial lift companies such as Skyjack, Genie and JLG are also suffering from uncertain lead times.

Supply side – radical growth predicted in Europe

Both China and Europe rely heavily on political sentiment to drive lithium-ion battery sales. As a result of China’s small domestic oil reserves, it imports a large amount of it. As far as Europe is concerned, the EU has enacted legislation binding the group to ambitious emissions reductions. Thus, the desire for energy security explains much of the motivation for developing battery technology. In addition, higher oil prices – another byproduct of the Ukraine conflict – could offset higher electric forklift battery costs. As a result of rising nickel, lithium, and other materials prices, electric forklift batteries will be 40% more expensive in 2022 than in 2021. Lithium iron phosphate batteries are in high demand.

Sales can be energized by lithium batteries for forklift dealers

Industry experts do not expect supply chain stability anytime soon. It is unlikely that pre-pandemic lead times will return before 2024. Meanwhile, logistics and third party logistics companies are running longer hours and putting extra strain on their forklift batteries. Many applications use lead-acid batteries that won’t last until the lease term ends, creating a real risk of disruptions and downtime. Maintenance is difficult to procure, and replacements can take years.

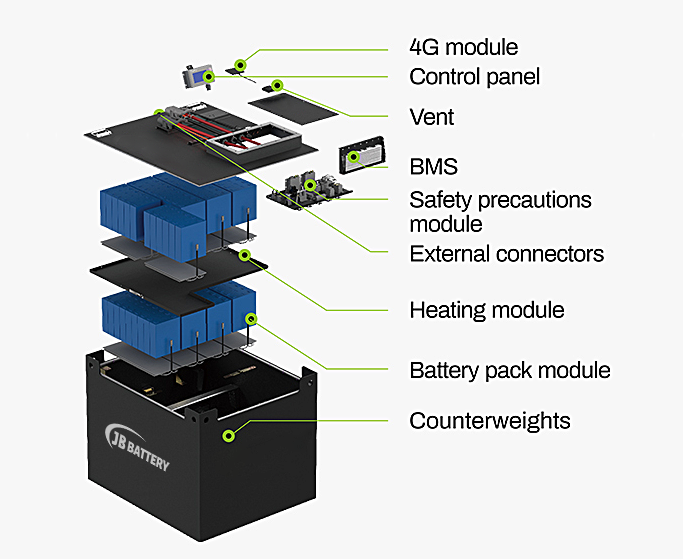

By adopting JB Battery lithium batteries, forklift dealers will be able to offer the following solutions to their customers in 2022–2023.

1. Upon expiration of the lease (or when uptime and maintenance labor costs appear to be declining), lead-acid batteries can be replaced with lithium batteries to maintain operations. Lithium batteries can power the new trucks when they arrive. This step will improve performance, not just sustain it.

2. Renting forklifts can mitigate the shortage of new equipment to replace equipment that is reaching its end of life. Dealers can create an attractive and profitable price model with advanced Lithium-Ion Battery

with modern data capabilities and triple the life of lead-acid batteries.

3. By helping their clients with a practical solution, Industrial Lithium Battery Manufacturers are improving their position in the rapidly growing lithium battery market. In the years to come, practical knowledge and experience with lithium technology will drive sales. IoT connectivity will offer opportunities for equipment uptime, operator safety, fleet optimization, and energy savings. Meet the gold standard in MHE batteries for Class I, II, and III forklifts.