What is the importance of printed circuit board assembly?

Printed circuit boards are a critical component of electronic devices and computer systems. They serve to hold the components which make up an electrical circuit, as well as provide pathways for the flow of electricity. A printed circuit board assembly (PCBA) is an assembled product created by combining the printed circuit board with other components such as wires, heat sinks, connectors and more in order to create a single unit that can be easily connected and disconnected from other electronics or power sources.

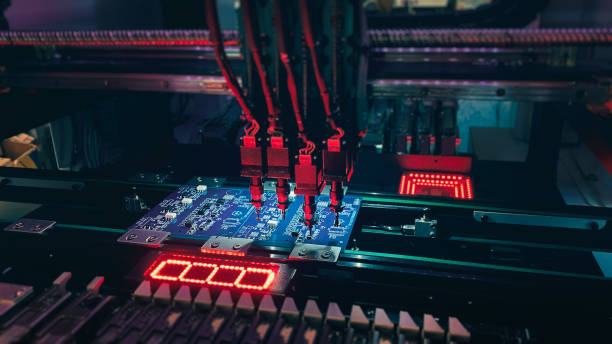

Printed circuit board assembly is a necessary step in electronics manufacturing.

PCB assembly is a necessary step in electronics manufacturing, and it helps with several aspects of the overall process. In general, PCB assembly makes the product more reliable by helping to ensure that components are installed correctly and in the right places.

It also allows for testing and inspection procedures to be performed during the manufacturing process, which can help identify defects before they become problems. Finally, it allows for functional testing of each individual part before final integration into an electronics device or system.

To meet demands of the consumers, printed circuit board assembly is vital.

PCBA is not just a way to make money, it is a way to help people. It helps manufacturers meet the needs of the consumers and save them time and money. PCBA is also a way to help people. It helps manufacturers meet the needs of the consumers and save them time and money. They can be used in many different products, such as smartphones, computers, medical devices, and more.

Helps in servicing and maintaining the board better

PCB assembly is a process that helps manufacturers improve the quality of the product, which ultimately helps in servicing and maintaining the board better. This is especially true when it comes to complex printed circuit boards (PCBs).

Printed circuit boards are used in many electronic devices including computers, cell phones and medical equipment to name a few because they provide a communication pathway between multiple components. A PCB assembly service ensures that any issues with your board can be corrected quickly before they become problems for your customers who rely on these systems day after day.

Testing and inspection procedures become easier in the case of PCB assembly.

PCB assembly allows for testing of the board before and after assembly. This makes it easier for companies to test their products for quality assurance purposes. They can either test the entire board or individual components, depending on what their needs are. Once a board has been assembled, it can be tested again to ensure it is functioning properly before being shipped out to customers.

Helps manufacturers make improvements

Printed circuit boards play an important role in the production process. In addition to helping manufacturers make improvements, the printed circuit board assembly (PCBA) process can result in three main types of benefits:

- Improvements made to the product itself

- Improvements made to the manufacturing process

- Improved quality of the finished product

Conclusion

Electronics are becoming more and more embedded in our everyday lives, and printed circuit boards (PCBs) are an integral part of making this possible. PCBs are central to just about any electronic device that you can imagine — from computers and cell phones to cars and planes. They provide a way for all kinds of components like transistors and capacitors to be connected so that they can work together as a system.