The benefits of UV adhesive curing are numerous

As one of the most advantageous methods for quickly curing adhesives, UV waterproof adhesive curing offers powerful advantages as well as seemingly limitless applications. The term UVA, UVB, or UVC light refers to electromagnetic radiation that can be broken down into various wavelengths between 10 and 400 nanometers.

UV wavelengths possess so powerful electromagnetic properties that they can cure (dry and harden) many types of materials instantly, including polymer resins, adhesive coatings, inks, and varnishes. A wavelength’s properties determine whether it will work well in a particular application, and are referred to as a nanometer (nm).

A UVC light bulb reaches a wavelength of 200 to 280 nm, delivering shorter wavelengths for germicidal, sterilization, and purification applications, eliminating bacteria and viruses from air and water instantly. As UVA (315-400nm) and UVB (280-315nm) light creates a photochemical reaction with a variety of polymers and adhesives, they have numerous applications, providing both economic and environmental benefits.

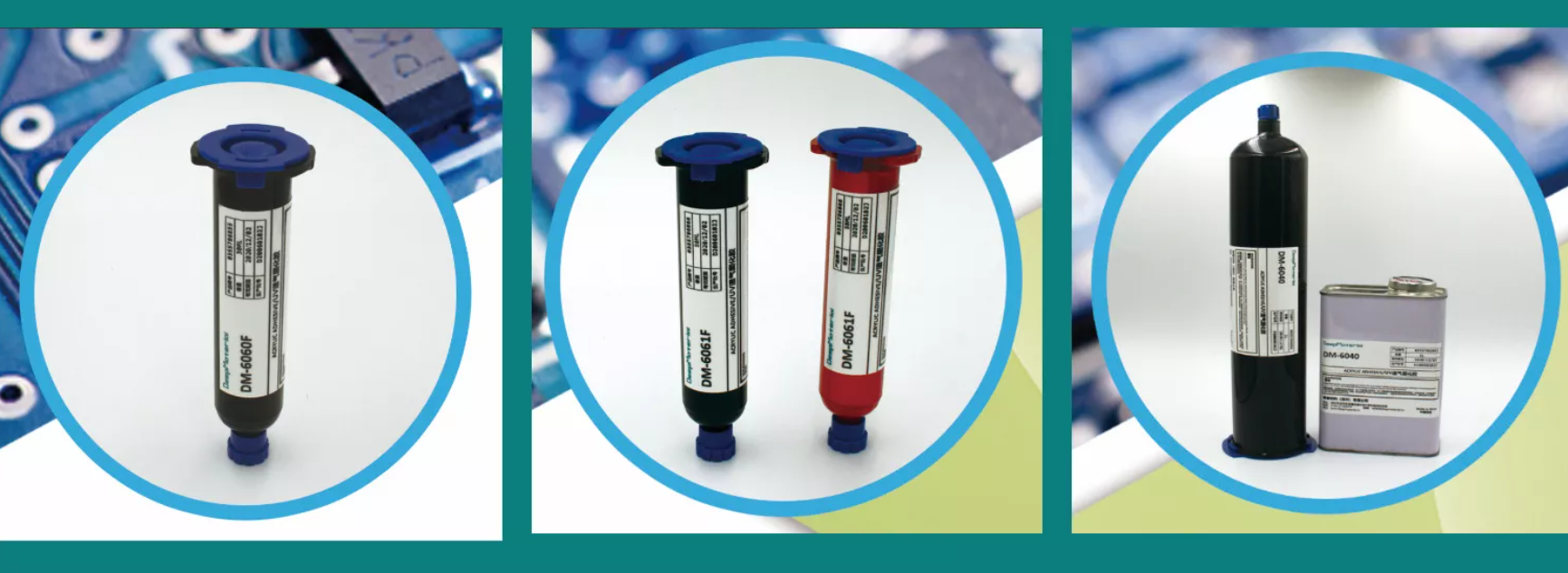

DeepMaterial is a global leader and UV Adhesive Manufacturer of UV lighting solutions, including UV adhesive curing applications, for OEMs worldwide.

Applications Using UV Curing for Adhesives, Filling and Bonding

The UV adhesive curing process is used for a variety of manufacturing processes, such as:

The aerospace industry

UV adhesive curing provides strength and durability under extreme temperatures while retaining clear optical quality.

Devices for medical and dental use

In the medical and dental fields, items such as optical lenses and sterilized devices need to be of consistent quality and sterilized.

The electronic industry

It is possible to use adhesives to cover vital electrodes, where a peel off film will be required to remove easily for installation, while providing reliable protection during packaging and transportation.

It can be used as a permanent adhesive to bond glass, metal, and plastic for long-term use.

The military

In extreme conditions, precision applications require long-lasting durability and dependability.

Ink-Jet Printing

A UV curing device is used in several printing applications to instantly dry inks on papers, brochures, and different types of cardstock.

Fiber Optics

During fiber optic cable assembly into glass tubing, UV lighting provides a tight seal.

Instantly bonds glues and fillers to glass tubing and wire connectors to ensure consistent LED or LCD lighting.

Labeling on Products

Dries inks and varnishes in company logos on plastics, glass, and adhesive labels in an instant.

Advantages of UV Adhesive Curing

Productivity

The productivity of UV cure adhesives, with their ability to almost “cure on a dime,” cannot be matched or matched. The fact that a full and permanent cure can be achieved in just a blink of an eye is undeniable.

Permanency

A second factor that is advantageous to UV cure adhesives is the degree to which they promote the degree of permanence they have. Occasionally, adhesives can serve as a temporary fix for an issue or temporarily solve the problem, however when they are repeatedly used or exposed to the elements, they begin to wear out. On the other hand, UV cure adhesives are much more permanent, lasting much longer and enduring much longer.

Flexibility

While it’s obvious that instant means instant when it comes to applying UV light, most folks are not aware that UV cure adhesives allow for an unlimited open time without UV light applied. This means flexibility for contractors or applicators. UV cure adhesives do not require running the clock to meet an open time deadline, as some adhesives do. It is unnecessary for applicants to rush or potentially waste time and money by doing the job over or unable to multitask.