What Are The Proper Scissor Lift Safety Requirements?

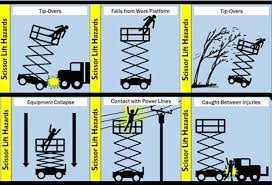

Using a scissor lift is an ideal choice for many contractors and companies working in the construction industry. However, not all of them are adequately aware of their safety requirements. Here are some essential proper scissor lift safety requirements.

The Basics:

Scissors lifts are a great way to get the employees up and down from heights safely and efficiently. There are a few basic rules that one should follow when using them, though, to ensure that everyone is safe while on the job.

- Make sure the scissors lift has sufficient power and strength. It could fall apart while being used, causing injury or even death if it doesn’t.

- Always wear proper safety gear when operating a scissors lift—This includes hard hats and safety goggles (or glasses).

- Never use scissors lifts in areas with high winds or other weather conditions that could cause instability in the lift’s movement or structure.

Avoid Overloading the Machine:

The proper scissor lift safety requirements are essential when using any equipment. The most basic of these is to avoid overloading the machine. Overloading can cause the engine to malfunction and may even cause injury if you are on board at the time. When first using a scissor lift, it’s essential to follow all instructions provided by the manufacturer regarding how much weight it can hold.

One should also check for wear and tear on your equipment before operating it. If there are any problems with the scissor lift, contact a professional immediately so they can repair or replace it before it is used again!

Performing Proper Inspections:

It is essential to perform regular inspections of the scissor lift. Doing so can catch any potential problems before they become a severe issue. This will help keep the ride in top condition and ensure it is safe and reliable.

Here are some of the most important things to check when performing an inspection:

Checking for oil leaks: Oil leaks can cause severe damage over time, so it is essential to check them regularly. If there are any leaks spotted, have them repaired.

Checking for loose bolts: Loose bolts can cause severe damage over time and make it more difficult for you to operate safely and efficiently. Make sure all bolts are correctly tightened before using your lift again.

Checking for cracks in plastic parts: Cracks in plastic parts could mean that they are about to break or crack completely, which could lead to severe injuries if not fixed immediately after being discovered.

The amount of times inspections are done on the type of lift. Most lifts require a weekly review, but some may need daily or monthly checks.

If there is uncertainty about how often one should perform the inspections, consult with your manufacturer or read their instructions for proper care.

The Safety of Your Employees:

The safety of the employees is one of the most important things you must consider when choosing a scissor lift. In an unsafe environment, they will not be able to do their jobs properly and could be hurt or injured. One needs to ensure that the chosen scissor lift has been approved by the American National Standards Institute (ANSI), which means it has met all of its safety standards. This will ensure that the employees are safe on the job site and that you are adhering to the company’s workplace safety policies.

Takeaway:

The proper safety requirements for using a scissor lift are numerous, and this list is by no means exhaustive. But before the employees get on one, ensure they know these essential precautions. More than that, ensure they know how to operate the lift properly. Only then will one be able to prevent injuries and accidents.